產品描述

基于蔡司METROTOM 的工業計算機斷層掃描(CT)

利用蔡司的工業計算機斷層掃描系統,僅需一次 X 射線掃描,即可順利完成工件的測量和檢驗。標準的驗收檢測、精密工程和完善的校準程序可確保系統的追蹤性。配備線性導軌及轉臺,滿足客戶對精確性的高要求。

第三代新款蔡司METROTOM 1500

面向未來的質量控制——今天

十二年來,蔡司METROTOM系列一直為質量控制提供可靠的CT技術。第三代計算機斷層掃描(CT)系統蔡司METROTOM 1500極好地證明了先進可靠的X射線技術不再是未來的愿景。今天,您可以使用面向未來的質量控制。

看得更多。

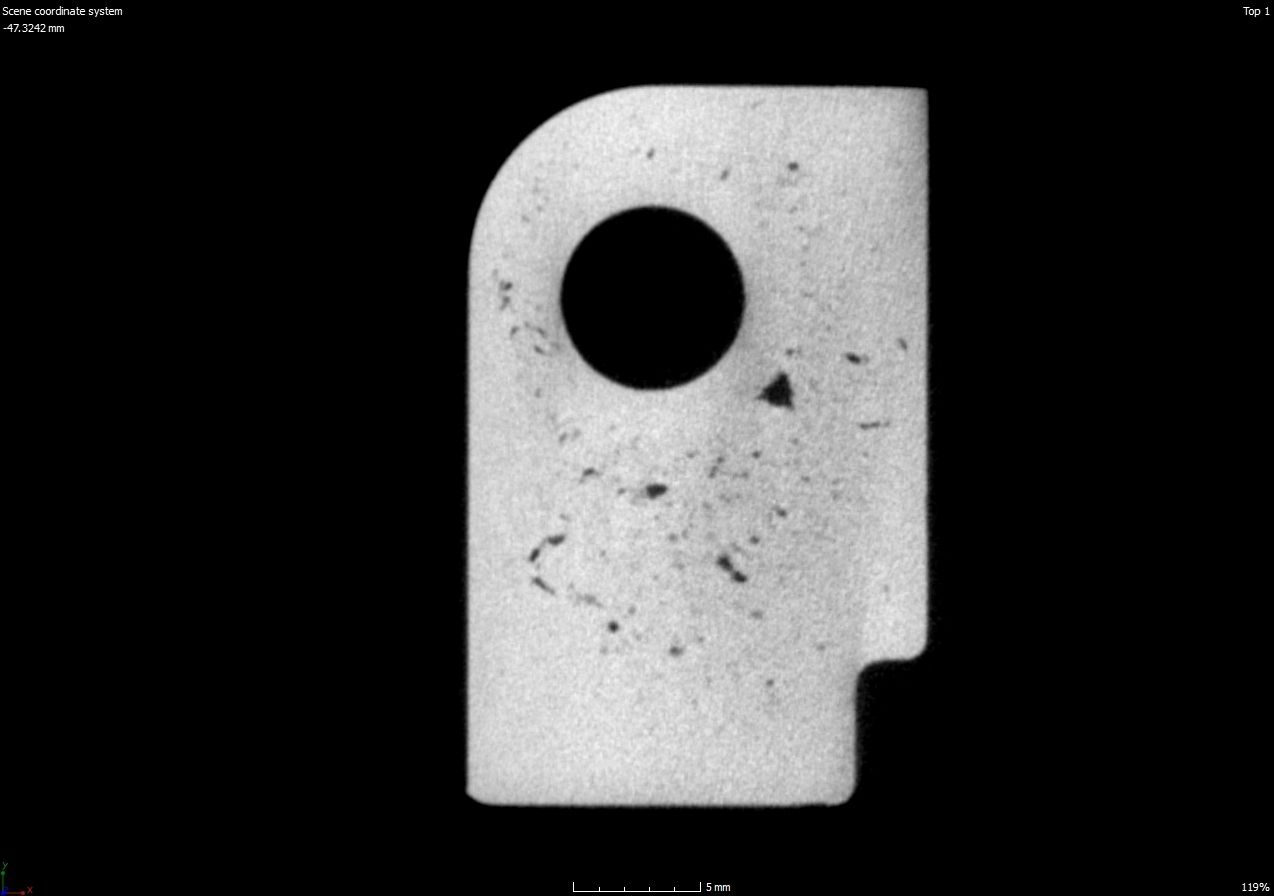

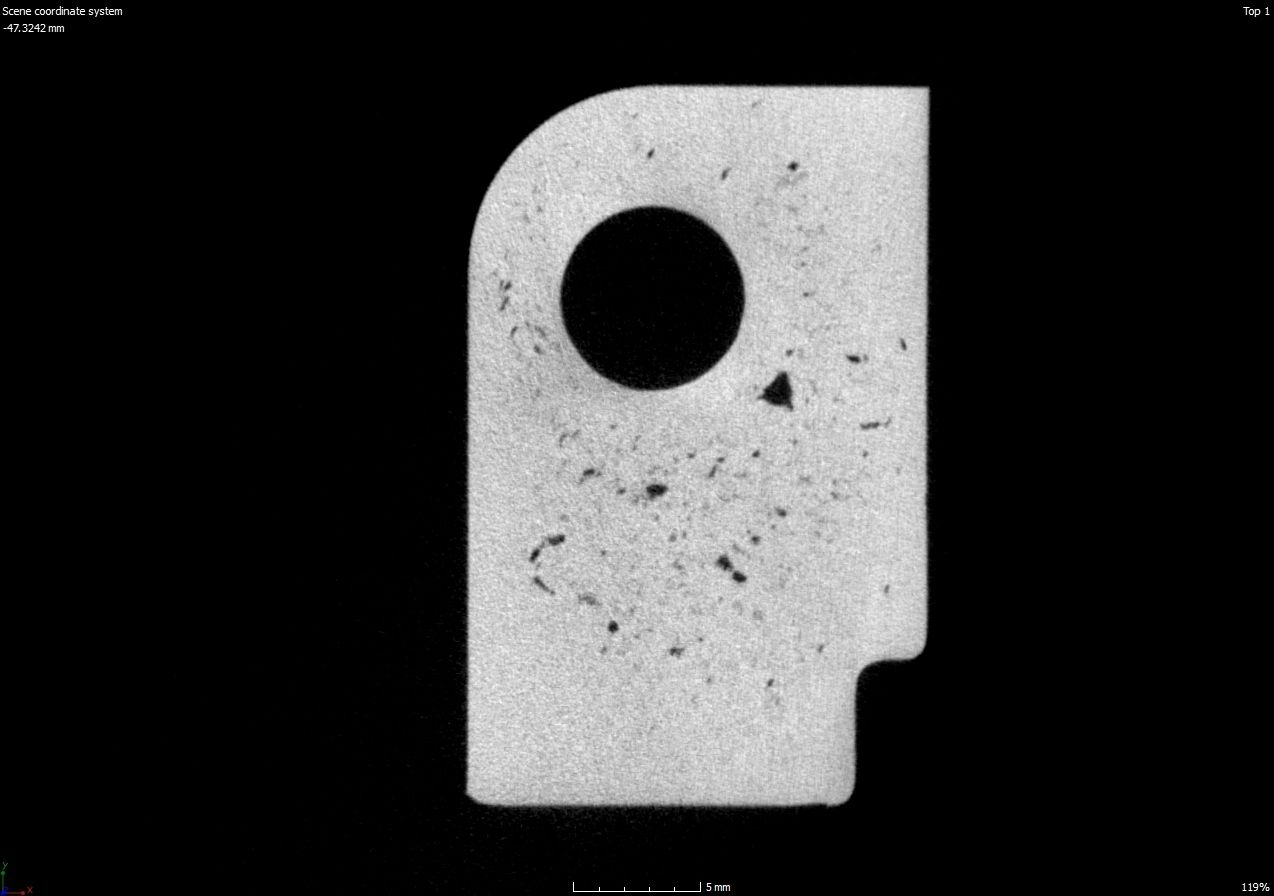

在第三代系統中,新的3k檢測器可生成更高分辨率的3D體數據集,即更多體素可以檢測到更小的缺陷。

掃描更快。

通過檢測器的不同操作模式,掃描時間可減少多達75%,同時獲得與2k檢測器相當的體素尺寸。

蔡司METROTOM系列

METROTOM 800 130 kV

高精準度

部件尺寸 | ●○○○ |

精度 | ●●●● |

時間 | ●○○○ |

面積 | ●●●● |

密度 | ●●○○ |

分辨率 | ●●●● |

ZEISS METROTOM 800 225kV HR

快速獲取,高密度的部件和細節描述

部件尺寸 | ●●○○ |

精度 | ●●●○ |

時間 | ●●○○ |

面積 | ●●○○ |

密度 | ●●●○ |

分辨率 | ●●●○ |

ZEISS METROTOM 1500

即使對于非常大的部件也能實現更多的靈活

部件尺寸 | ●●●● |

精度 | ●●○○ |

時間 | ●●●● |

面積 | ●○○○ |

密度 | ●●●● |

分辨率 | ●●●○ |

使用蔡司METROTOM輕松進行測量

測量與檢驗整體部件

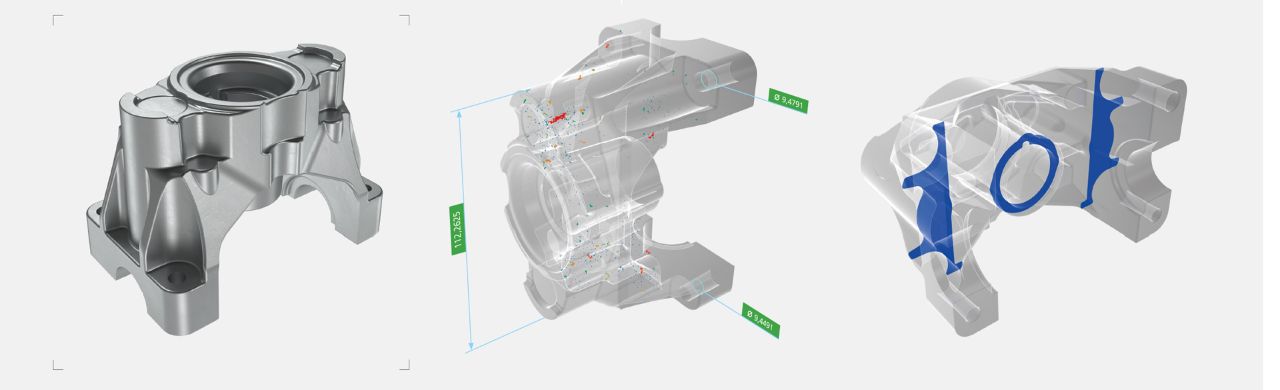

蔡司METROTOM是一種工業計算機斷層掃描系統,用于測量和檢查由塑料或輕金屬制成的完整部件。而在利用傳統測量機測量時,此類隱藏性的結構信息只有將零件通過費時的層層破壞方能獲得。

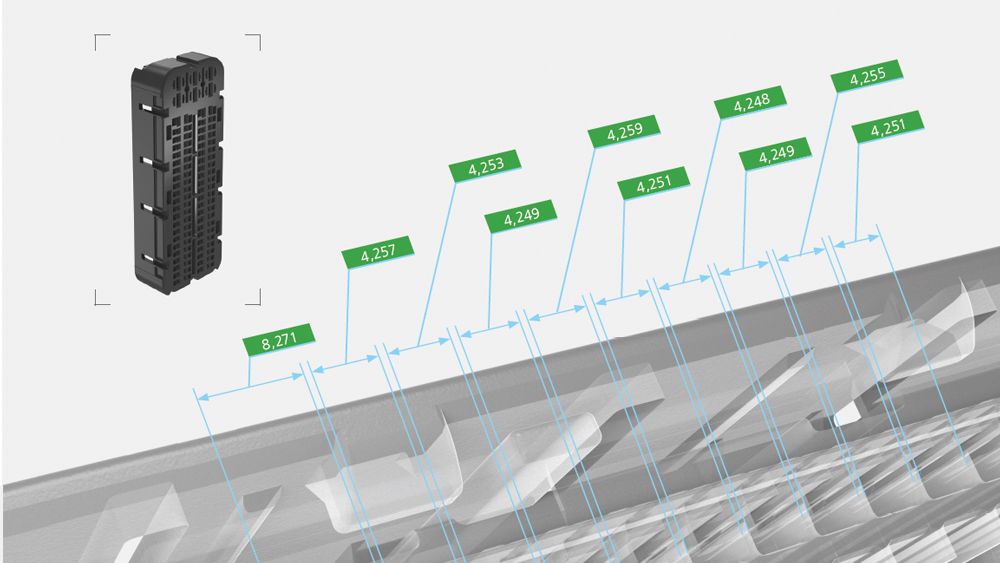

輕松且精準地進行多樣化特征檢測

利用蔡司METROTOM 計算機斷層掃描系統可一次掃描海量的零部件特征。這些測量結果非常精確,且具可追溯性。和接觸式測量方法不同,蔡司METROTOM 獲取海量測量點時,時間顯著縮短。

Comprehensive CT data analysis in 3D

The easy-to-use and even for beginners suitable analysis software GOM Volume Inspect allows complete CT data analysis in 3D. Geometries, shrinkage holes or internal structures and assemblies can be analysed precisely. Even the smallest defects become visible through individual sectional images and can be automatically evaluated according to various criteria. You can also load volume data of several components into a project, perform a trend analysis and compare the analysis with CAD data. In this way, the quality of your component can be exactly determined and documented - and all this in just one software.

DAkkS calibration for increased confidence

Higher quality standards in the automotive, medical or pharmaceutical industry often make it necessary to rely on accredited CT inspection procedures. These guarantee an objective, standard-compliant measurement of parts according to VDI/VDE 2630 part 1.3. DAkkS certification is accepted worldwide, which eliminates the costs for multiple assessments. Now the DAkkS calibration is also available for the computer tomographs of the ZEISS METROTOM 800 and 1500 series! Benefit from its advantages: save costs and create more trust for your customers.

Available options

Automated filter changer

Manual filter pre-settings to scan a wide variety of parts with different materials and material compositions are no longer necessary thanks to the automatic filter changer. In this way, you can achieve reliable results even faster.

ZEISS FixAssist CT

With ZEISS FixAssist CT, you can reduce machine downtimes by up to 80%. Simply position the workpiece on the pallet outside the machine before measurement, place the pre-adjusted part in the computer tomography system and start scanning immediately.

ZEISS Tomostage

You would like to capture several parts in one scan? This is possible with the carbon fiber tower specially developed for CT applications. In this way, the measuring times per part can be drastically reduced – for increased throughput.